In industry operations, some tools do not always hog the limelight, but their influence on productivity, quality, and safety cannot be denied. Metal strip brushes are a case in point. They look simple, but the fact that they are so versatile makes them a must-have in several industries, including manufacturing and packaging, electronics, and construction, among others.

In this blog post, we will discuss what metal strip brushes are, how they are produced, and their numerous industrial uses so you can see why selecting the right supplier, like a reliable industrial brush manufacturer, is essential for your business.

What Are Metal Strip Brushes?

Metal strip brushes are a tightly packed line of bristles firmly fixed into a metal channel. The metal support, usually made of steel, stainless steel, or aluminium, gives it the necessary stiffness and strength. At the same time, the bristles are produced from natural fibres, man-made materials, or metal wires based on the specific use.

These brushes can be made in straight strips, curved patterns, or even spirals, thereby making them versatile for various operational requirements. Most industries prefer metal strip brushes due to the balance of strength, flexibility, and long lifespan.

How Metal Strip Brushes Are Made

A good industrial brush manufacturer usually follows these steps in making quality metal strip brushes:

- Material Selection – Selecting the appropriate bristle material (e.g., nylon, polypropylene, stainless steel wire), dependent on the end application.

- Channel Forming – Forming the metal channel to retain the bristles firmly.

- Bristle Insertion – High-tensile bristles are pressed into the channel.

- Cutting & Shaping – The strip is cut to size and formed (straight, arc, or coil).

- Quality Inspection – Verification of uniform bristle density, precise dimensions, and longevity.

Key Benefits of Metal Strip Brushes

Selecting metal strip brushes instead of other types of brushes has several benefits:

- Sturdiness – The metal backing keeps the brush in shape even when under pressure.

- Flexibility – Can be designed to a range of sizes, densities, and shapes.

- Personalizable Bristle Materials – For light cleaning or heavy scrubbing applications.

- Endurance – Durable and resistant to wear in harsh environments.

Industrial Uses of Metal Strip Brushes

The flexibility of metal strip brushes is such that they’re applied in nearly all key industrial industries. Below are some typical applications:

1. Sealing and Weatherproofing

Metal strip brushes are typically fitted in doors, shutters, and machines to cover openings and keep away dust, air, or light penetration. They also enhance energy efficiency in industrial settings.

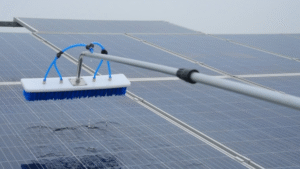

2. Conveyor Belt Cleaning

In production and packaging factories, the brushes sweep conveyor belts, clearing away dust, grime, or loose particles to ensure production lines are uninterrupted.

3. Surface Preparation

Before painting, coating, or welding, metal strip brushes clean and prepare surfaces by removing rust, scale, or impurities.

4. Static Control in Electronics

When produced with conductive fibres, they help counteract static electricity in sensitive electronics production.

5. Material Guiding

In woodwork, printing, and textile manufacturing, strip brushes push materials through machines in precise alignment to avoid misalignment or damage.

6. Metal Deburring

Industrial brush firms make heavy-duty wire-filled metal strip brushes for deburring cut edges and eliminating burrs following cutting or machining procedures.

Why Hire a Reliable Industrial Brush Company?

Not every metal strip brush is alike. The appropriate supplier guarantees:

- High-Quality Materials – For extended lifespan and consistent performance.

- Precision Manufacturing – Precise sizing and bristle density.

- Customisation Options – Shapes, sizes, and materials tailored to your unique needs.

- Industry Expertise – Understanding of the ideal brush type for your use.

A trusted industrial brush company not only offers a product but also advises you on choosing and maintaining it for optimal performance.

Tips for Maintenance of Metal Strip Brushes

To prolong the longevity of your strip brushes:

- Clean them regularly to avoid build-up.

- Use care not to apply too much pressure when operating to prevent bristle damage.

- Store brushes in a dry location to avoid metal channel corrosion.

- Replace brushes when bristle wear impairs performance.

Final Thoughts

Metal strip brushes are an industrial unsung hero, working quietly in the background to leave surfaces cleaner, production lines more efficient, and seals better. From heavy-duty factory cleaning to sensitive static control in electronics, their applications are all but limitless.

The key is choosing a supplier that understands your industry, offers customisation, and guarantees quality. That’s where partnering with a reputed industrial brush company makes all the difference.