Let’s be honest. No one grows up dreaming of talking about brushes.

However, here’s a secret that most industries don’t discuss.

Behind clean conveyor belts, perfectly finished metal sheets, sanitized food equipment, and shiny pharma tanks… are brushes working nonstop. And for decades, no one cared what they were made of.

Until now.

In a world that’s rethinking everything, from how we eat to what we wear, even brushes for industrial use are getting their eco moment. And Ganesh Brush Manufacturers, a Pune-based company with roots in the 1980s, is quietly leading that movement with special & customized brush solutions built for both performance and sustainability.

This isn’t about some vague “green promise.” This is about swapping out bristles, reducing landfill waste, and rethinking how machines stay clean without hurting the planet.

So let’s break it down.

Wait. Industrial Brushes Can Be Eco-Friendly?

You’d be surprised.

Most people think of industrial brushes as tough, synthetic, disposable tools. Something you toss after a few weeks on the job. But what if even industrial disc brush manufacturers could help reduce plastic waste, one bristle at a time?

That’s precisely where biodegradable bristles come in.

These bristles are made from natural or semi-natural materials that break down more easily than those derived from petroleum-based plastics. Think rice husk, coir, corn-based polymers, or even bamboo-fibre-reinforced blends.

Now, we’re not saying that every brush in your factory has to be 100% biodegradable from the start. But if your company has even the slightest interest in reducing its environmental footprint, this is a surprisingly practical place to start.

What Are Biodegradable Bristles?

Let’s make it easy.

Biodegradable bristles aren’t a gimmick. They’re made from materials that return to the earth naturally and safely, once their job is done.

Here’s what’s trending in the eco-brush world:

- Plant-based Polymers (like PLA): Made from cornstarch or sugarcane, these bristles mimic the durability of plastic but decompose more quickly.

- Natural Fibre Blends: Coir (coconut fibre), jute, or agave fibres reinforced with minimal synthetic binding.

- Recycled Bioplastics: Some bristles are made from post-consumer waste with additives that help them degrade faster.

Each has its strengths and ideal use case. The trick is choosing the right type for the job, and that’s where companies like Ganesh Brush Manufacturers come in with their special & customized brush design process.

But… Do These Brushes Actually Work?

Let’s bust the biggest myth right here.

Biodegradable doesn’t mean weak.

Eco-friendly brushes can be just as strong, heat-resistant, and chemical-safe as traditional ones. In fact, with the right bristle material and base design, they often perform better in delicate tasks where micro-scratches or contamination risks are a concern.

Take this use-case, for instance:

Problem: A food-grade stainless steel conveyor belt in a bakery needed regular cleaning. Nylon brushes worked well but had to be replaced every few weeks and couldn’t be composted.

Solution: Switching to a biodegradable coconut fibre + PLA blend provided equal cleaning power, longer life (since it was less abrasive), and could be discarded into the facility’s compost bin.

That’s not just smart. That’s sustainable engineering.

Who is Using Eco Brushes Right Now?

This isn’t some futuristic idea.

FMCG, pharma, chemical, and textile companies in India are already testing eco-brushes for specific cleaning, scrubbing, and polishing tasks.

Here are 3 scenarios where biodegradable brushes are already winning:

1. Food & Beverage Plants

For machinery where hygiene is non-negotiable, synthetic micro-particles can be a problem. Natural fibre brushes reduce the chance of shedding plastic onto surfaces.

2. Cosmetic & Personal Care Production

Where “clean beauty” starts from the factory floor. Brushes made from natural blends align with the brand’s overall sustainability narrative.

3. Green Certified Buildings & Smart Factories

Yes, some factories pursue LEED certification or strive for zero-waste goals. Swapping out brushes for industrial processes is a low-hanging fruit in their sustainability checklist.

Let’s Talk Tech: How Are These Brushes Made?

This is where things get cool.

At Ganesh Brush Manufacturers, the process of making an eco-friendly brush begins with understanding the machine and material on which the brush will be used. Unlike off-the-shelf tools, these are built for precision.

Here’s a simplified version of how it works:

- Understanding Your Surface & Pressure Needs: Whether you’re cleaning a delicate sensor or a rough steel pipe, pressure tolerance matters.

- Choosing the Right Bristle Mix: Ganesh helps you pick the biodegradable fibre based on chemical exposure, temperature, and contact time.

- Mount Design: Be it a disc brush, strip, cylindrical, or rotary brush, the mount is made with reusable or recyclable materials.

- Customisation for Motion: Linear, rotational, oscillating, every brush behaves differently in different movements. Ganesh aligns design to your system’s kinematics.

This is why they’re one of the leading industrial disc brush manufacturers; they don’t just sell brushes. They co-create them with you.

What Makes Ganesh Brush Different?

They’ve been around since before sustainability became trendy.

Founded with roots dating back to the 1980s and formally established in 2008, Ganesh Brush Manufacturers is part of a rare breed: it combines old-school engineering insight with modern sustainability thinking.

A few reasons clients stick with them:

- Full control on materials: From coir to PLA, they source responsibly and even help you choose compost-friendly variants.

- In-house design and tooling: Nothing is outsourced. So your brush fits and lasts.

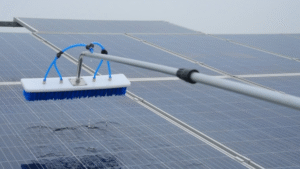

- Problem-solving mindset: Whether it’s a new conveyor belt in a chocolate plant or a polishing line for solar panels, they prototype till it works.

- Flexible for small-batch orders: You don’t have to order 10,000 units to go eco. Even custom orders are welcome.

If you’re looking for a specialised & customised brush partner that aligns with your green goals, this team is worth considering.

Can You Use Biodegradable Brushes in Heavy Industries?

Short answer: Yes, but with caveats.

Some heavy-duty tasks (like steel descaling or high-heat polishing) still rely on traditional wire or synthetic blends because of extreme stress. But Ganesh is already experimenting with hybrid brushes that combine a sustainable outer layer with a durable core.

Think of it like this:

- 60% biodegradable where contact happens

- 40% durable synthetic for the load-bearing base

This hybrid approach maintains high performance while significantly reducing plastic waste.

Is It More Expensive to Go Eco with Brushes?

Not always.

Initial cost per unit may be a bit higher for biodegradable variants, but the real savings show up over time:

- Fewer replacements due to gentler cleaning

- Better brand reputation for going green

- Easier compliance with environmental regulations

- Lesser waste management cost for large units

And don’t forget: when sustainability is built into the design, the brush isn’t just a tool. It becomes a value creator.

So, how do you get started?

If you’re reading this thinking, “Should we try this in our factory?” the answer is, yes, start with just one brush.

Pick a non-critical use case. Discuss a sustainable version with Ganesh. Compare performance. Watch the numbers.

And if it works?

Scale it across departments. Add it to your green checklist. Talk about it in your ESG report.

Sustainability doesn’t have to mean reinventing everything. Sometimes, it starts with a bristle.

The Green Future Has Tiny Fibres

The shift to sustainable operations doesn’t always need massive investment or tech disruption. Sometimes, it starts in the least glamorous corner of your factory , the one where machines get cleaned, parts get scrubbed, and surfaces get polished.

That’s where the new industrial sustainability story is unfolding. One biodegradable bristle at a time.

And thanks to companies like Ganesh Brush Manufacturers, going green no longer means compromising on performance.

It just means… you’re brushing better.

Ready to Switch to Eco-Friendly Industrial Brushes?

Whether you need a special & customized brush, help from trusted industrial disc brush manufacturers, or advice on the best brushes for industrial operations that align with your sustainability goals , Ganesh Brush Manufacturers is your partner in progress.

Drop them a message. Start a conversation. And let the transformation begin, one brush at a time.

Ganesh Brush Manufacturers, Built to Clean. Designed to Care.