By the way, your surface isn’t just a surface. It’s a story.

A story of grime that never gives up. Of particles hiding where your team can’t see. Of moving belts, sharp metal, and dust that threatens to stall your machines mid-shift.

And at the centre of this unsung battle?

- Not a robot.

- Not a fancy app.

- Not a cloud-powered anything.

Just a brush.

Yes, really.

Whether it’s that flexible strip brush sealing gaps on a moving conveyor, the disc brush doing the dirty work of deburring sharp edges, or the cylindrical brush cleaning sheets faster than your intern can say “ISO 9001”, these tools literally keep industries running.

So let’s settle this once and for all.

If you’re unsure about the differences between a strip, disc, or cylindrical brush, this is your guide. Not a catalogue. Not jargon. Just real answers from a factory-world point of view.

Meet the Three Main Characters

Think of these three as teammates. They all do important jobs. However, each has its unique mood, vibe, and personality.

1. Strip Brushes: The Silent Problem Solver

Imagine a long brush strip, flexible, custom-sized, and often tucked into a metal or plastic channel. It doesn’t spin. It doesn’t buzz. It just sits there and quietly saves your production line.

Common jobs:

- Sealing gaps in conveyor systems

- Preventing dust or fumes from escaping

- Guiding fragile parts

- Acting as a barrier without damaging the product

Why choose this?

If you’re trying to control direction, prevent spillage, or shield something from external damage, a Strip Brush Supplier will tell you it’s your best friend.

The mood: Strip brushes are like your warehouse supervisor. Quiet, efficient, always on time.

Typical industries: FMCG, packaging, pharmaceuticals, electronics.

2. Disc Brushes: The Tough Deburrer

Let’s get one thing straight: metal doesn’t clean itself, especially not after cutting, grinding, or machining. That’s where disc brushes come in. These are flat, circular brushes that spin like a CD from the early 2000s, but way more useful.

Common jobs:

- Removing burrs from CNC-machined parts

- Cleaning stubborn buildup

- Texturing or polishing surfaces

- Preparing before painting or welding

Why go for it?

If your factory deals with sharp edges, rust, or surface inconsistencies, a Circular and Disc Brush is a must-have. It’s not just about cleaning, it’s about preparing parts for the next critical step.

The mood: Like a good mechanic, direct, a little loud, but gets the job done like nobody else.

Typical industries: Automotive, aerospace and metal fabrication.

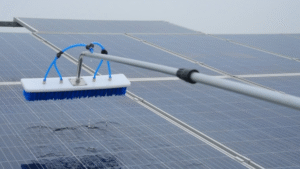

3. Cylindrical Brushes: The Conveyor Whisperers

Now imagine a roller that doesn’t just spin, but also cleans, guides, and polishes as the product rolls over it. That’s a cylindrical brush.

Also known as rotary brushes, these rotate on a shaft and efficiently cover wide surfaces.

Common jobs:

- Cleaning conveyor belts while in motion

- Washing & Peeling fruits, vegetables.

- Polishing & Dusting wood panels or glass cleaning.

- Applying liquids like coatings or lubricants, transfer of materials.

Why pick this one?

When your challenge is large surface area + speed, the Industrial Cylindrical Brush is unbeatable. It can clean or finish large volume of components in stipulated time without even blinking.

The mood: Like your most productive shift worker, multitasking without complaint.

Typical industries: Food processing, Automotive, steel rolling, glass polishing.

Strip vs Disc vs Cylindrical: Which One Wins?

Let’s break it down like a good chai-time gossip.

| Feature | Strip Brush | Disc Brush | Cylindrical Brush |

| Primary Action | Sealing, blocking, guiding. | Descaling, Scrubbing, Deburring, polishing | Cleaning, Dusting, Washing, conveying |

| Motion | Static | Rotational | Rotational |

| Mounting | Along edges or gaps | CNC, VMC and SPM Machines | With shafts |

| Best For | Protection & control | Surface prep & finishing | Continuous flow cleaning |

| Looks Like | A long hairy stick | A rotating pizza | A fuzzy rolling pin |

So, is one really better than the other?

No. It depends on your battlefield.

- If you’re sealing off gaps on a dusty conveyor belt, strip brushes will work without needing attention for months.

- If you’re dealing with sharp metal edges after machining, disc brushes will handle the mess like a pro.

- If you’re processing Tons of fruits a day or rolling large glass panels, you’ll need an Industrial Cylindrical brush doing the heavy lifting.

How to Choose the Right Brush (Like a Pro)

Here’s where most factories mess up. They order brushes like office supplies, blindly and based on price.

But brushes aren’t commodities. They’re precision tools. Here’s a better approach:

1. Know your surface.

Is it smooth, rough, sharp, greasy, soft, brittle? Brushes behave differently based on what they’re touching.

2. Understand the motion.

Will the brush stay still while parts move? Or will it rotate with them? Or both?

3. Decide on pressure.

Do you want a light touch to guide a product? Or a hard scrub to remove grime?

4. Think about material.

Brushes can be made with Nylon, Polypropylene, Stainless steel,Hair, Natural fibres, or even Abrasive filaments. Each one has a vibe of its own.

5. Talk to a real manufacturer.

Don’t just buy from an online catalogue. Call up a Strip Brush Supplier or an Industrial Cylindrical Brush expert like Ganesh Brush Manufacturers in Pune. They’ve been doing this since 1980, and trust us, they’ve seen every brush mistake that can happen.

The Hidden Costs of Choosing the Wrong Brush

Think it doesn’t matter? Here’s what can go wrong:

- Poor sealing from the wrong strip brush = contamination in food production or Clean Rooms

- Incorrect disc brush = Damaging Component RA value or dimensions.

- Wrong cylindrical brush = Streaks on glass panels, Issues in Material dusting, Material movement on conveyor.

One small brush error can trigger a quality-control nightmare.

Maintenance Tips Most Factories Ignore

Brushes aren’t just “install and forget.” You can make them last 30 to 50 percent longer by:

- Cleaning them weekly (compressed air is enough in many cases)

- Storing them upright or on racks to prevent bending

- Replacing worn filaments before they damage the product

- Lubricating the mounting system to reduce friction

- Keeping backups, don’t wait for a brush to die mid-production

Real-Life Example: The Tomato Factory That Switched Brushes

A food processing plant in Maharashtra was facing problems with tomato skins tearing during sorting. Their conveyor brush was too stiff.

They called in Ganesh Brush Manufacturers. Swapped it with a soft, cylindrical brush made from a mix of horsehair and poly. Result?

- 25 percent fewer rejections

- 3x longer brush life

- Happier QA team

Sometimes the difference between a failed batch and a clean one is a simple brush switch.

A Quick Word on Customisation

Here’s the beauty of working with a specialised brush maker: you can get brushes built exactly for your machine, your material, and your process.

Don’t settle for “standard size.” Especially if:

- Your conveyor has an odd width

- You’re handling delicate electronics or high-temp metals

- You want branding or colour coding for different brush zones

Ganesh Brush Manufacturers, for example, design everything in-house. Whether you want a V-shaped strip brush, a dense bristle disc, or a cylindrical roller with mixed filament zones, they’ve probably made it before.

Final Verdict: No One Brush Rules Them All

In the end, strip, disc, and cylindrical brushes aren’t competitors. They’re collaborators. Your factory might need all three, sometimes even on the same machine.

- Strip for sealing

- Disc for deburring

- Cylindrical for cleaning

Each one plays a role in keeping your workflow lean, clean, and cost-effective.

So instead of asking, “Which brush is best?”

Start asking, “Which brush is best for this job?”

Need Help Choosing the Right Industrial Brush?

If you’re feeling unsure, don’t leave it to guesswork or trial-and-error buying. Let the experts help.

With top manufacturers like Ganesh Brush Manufacturers, connecting you with the right tools, suppliers, and insights to scale smart.

From strip brush supplier leads to circular and disc brush configurations, or help sourcing an industrial cylindrical brush for your plant, we’ve got the network and the know-how to get it done quickly.

Reach out to us today.

And let your brush do more than just sweep. Let it solve.